DC12V 100mA Environmental Monitoring Unit With Alarm

Product Details:

| Place of Origin: | China |

| Brand Name: | ESTEL |

| Certification: | ISO |

| Model Number: | EA8016001 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1PC |

|---|---|

| Price: | Depending on Order Quantity |

| Packaging Details: | Carton |

| Delivery Time: | 15 days |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 20000PCS per month |

|

Detail Information |

|||

| Power Supply: | DC8-15V | Waiting Current: | 11mA DC12V |

|---|---|---|---|

| Capacity Of Anti Disassembly Contact: | 1A DC12V | Relay Capacity: | 100mA 12V, 30 Ω Resistance In Series |

| Calculator: | Microprocessor Control | Alarm Relay Output: | Solid Relay, Normally Closed Contact |

| Warm-up Time: | Immediately | Indicator Lamp: | Red LED Is On For 3 Seconds After Alarm |

| Highlight: | 100mA Environmental Monitoring Unit,DC12V Environmental Monitoring Unit,environmental rack monitoring unit |

||

Product Description

Outdoor Telecom Cabinet Shock Sensor 12VDC Digital Vibration Detector

With Alarm Relay Output And Microprocessor Control

Model: EA8016001

Function

The digital vibration inductive detector, equipped with microprocessor control, alarm triggering can be achieved by a single vibration amplitude, or by accumulating multiple vibration signals of different sizes within the time limit. The weak vibration signal will be shielded, but not accumulated to generate alarm. Only strong vibration or multiple times vibration will be considered as effective signal and stored in pulse counting memory. At the same time, it can set the sensitivity manually to ensure that the best working point can be set according to the environmental conditions - to prevent false alarm without reducing the sensitivity.

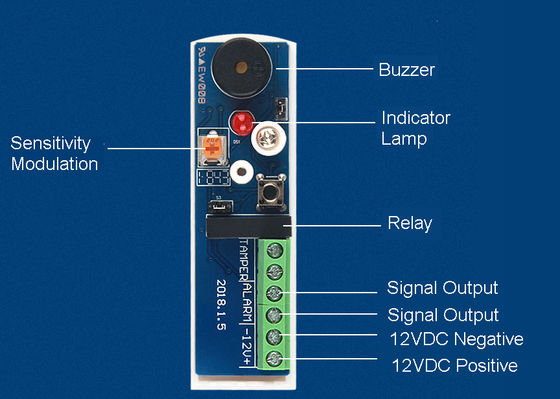

Wiring

Power terminal connected to 12V DC power supply

Alarm output connected to normally closed zone of alarm host

Anti disassembly output connected to normally closed zone of alarm host

Adjust sensitivity

First, turn the sensitivity potentiometer anticlockwise to the end. At this time, the sensitivity is the lowest. Slowly rotate VR clockwise to increase the sensitivity. Knock the protected surface (simulated attack force) at each sensitivity setting point, and pay attention to whether notice if the red light is on. If the red light is on for two seconds, it indicates an alarm. This sensitivity point is the correct setting point, and then try again knock with less force to test whether the sensitivity is too high.

The jumper cap on the circuit board of the detector is a high and low sensitivity regulator, which is high sensitivity when closing and low sensitivity when opening.

Specifications

| Inductive device | Vibration sensor |

| Calculator | Microprocessor control |

| Alarm relay output | Solid relay, normally closed contact (about 30 ohm internal resistance), maximum 100mA / 30V, open circuit in case of alarm. Normally open output model can be optional |

| Relay capacity | 100mA 12V, 30 Ω resistance in series |

| Sensitivity setting | Continuously adjustable |

| Warm-up time | Immediately |

| Anti disassembly | Normally closed contact, open the cover open circuit |

| Capacity of anti disassembly contact | 1A DC12V |

| Indicator lamp | Red LED is on for 3 seconds after alarm |

| Power supply | DC8-15V |

| Waiting current | 11mA DC12V |

| Working temperature | -20~50℃ |

| Shell | White flame retardant PVC |

| Dimension | 26×85×24mm, W×H×D |

| Weight | 50g |

Fixing and installation

Disassembly and combined installation

1. Remove the panel

Insert a small paper cutter or screwdriver to the gap beside the screw cover (see Figure 1), gently pry up the screw cover, loosen the screw, and then separate the surface cover and the bottom cover (see Figure 2)

![]()

2. Combination cover

Place the screw in the screw pit, then tighten the screw and carefully close the cover.

3. Installation

Fix the vibration detector to the protected surface.

![]()

Pictures

![]()

![]()